We offer you a portfolio of typically implemented control mechanisms for hollow and flat glass machines. See for yourself!

Hollow glass machines:

Level with drop weight control

Modular, station-by-station servo-pneumatic control system for the precise production of hollow glass containers.

Pusher

Stationary servo-electric/hydraulic ejection system for bottles. Very high repeat accuracy and axis synchronization up to 16 axes.

Drop distributor

The “glass drops” are distributed from the distributor to the individual machine stations. This requires highly precise but smooth movement of the distributor channel. This is ensured by special Sinus² acceleration/deceleration ramps.

Scissors

The shears hydraulically cut through the glass gob within 20 milliseconds.

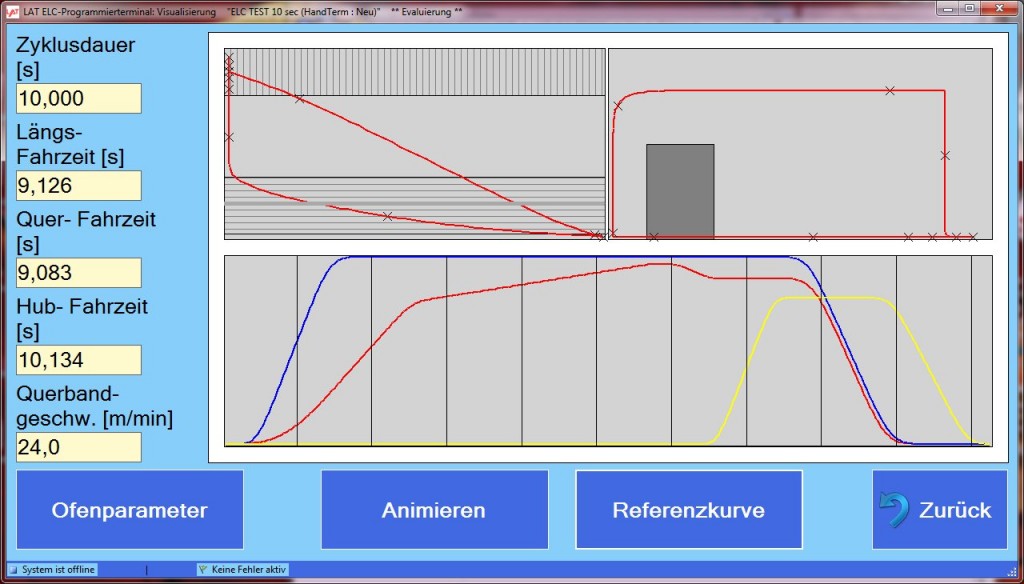

Slide-in unit

3-axis control system for handling hot glass bottles. These must be moved from a longitudinal to a transverse cooling conveyor belt. Up to 2000 bottles are turned over per minute.

Flat glass

12-axis hexapod glass bending machine

Highlight: Large showcase glass and shower cubicle panes with high precision requirements are hot-bent on these machines. The variable, reproducible production of even small batch sizes should be emphasized in particular.