“What makes us a specialist for electric drives? Individual and ultra-modern solutions in all sizes.”

We offer you electric drives from very small to large, e.g. a 2 x 200 watt drive for throttle adjustment with two DC geared motors: By integrating the power control with a power IC on the customer-specific board together with the 32-bit MCU and a graphics chip, a compact solution for a medical training device.

We can also offer you examples in the following areas:

- Coiler and stand drives for a rolling mill

- IHU (internal high pressure forming) machine with purely servo-electric axes

- ServoLinear axes

- Hysteresis measuring machine for compensator elements

Fancy a few interesting application examples?

Application example 1:

Coiler and stand drives for a rolling mill

During the modernization of a rolling mill, the DC motors (2 x 80 KW 1 x 120 KW) were retained for cost reasons, but equipped with new Siemens control systems (Sinamics). The technological functions such as tension control and AutoSlowdown with collar calculator etc. have been integrated into our thickness control system.

Application example 2:

Internal high-pressure forming machine with purely servo-electric axes:

- 9 axes of this machine are servo-electrically controlled

- 2 axles are hydraulic b/w axles

- A 90 kW servo motor was used for the forming axis. This is capable of achieving a maximum travel speed of 400 mm/sec, but is also reproducible to an accuracy of 1/100 mm.

Application example 3:

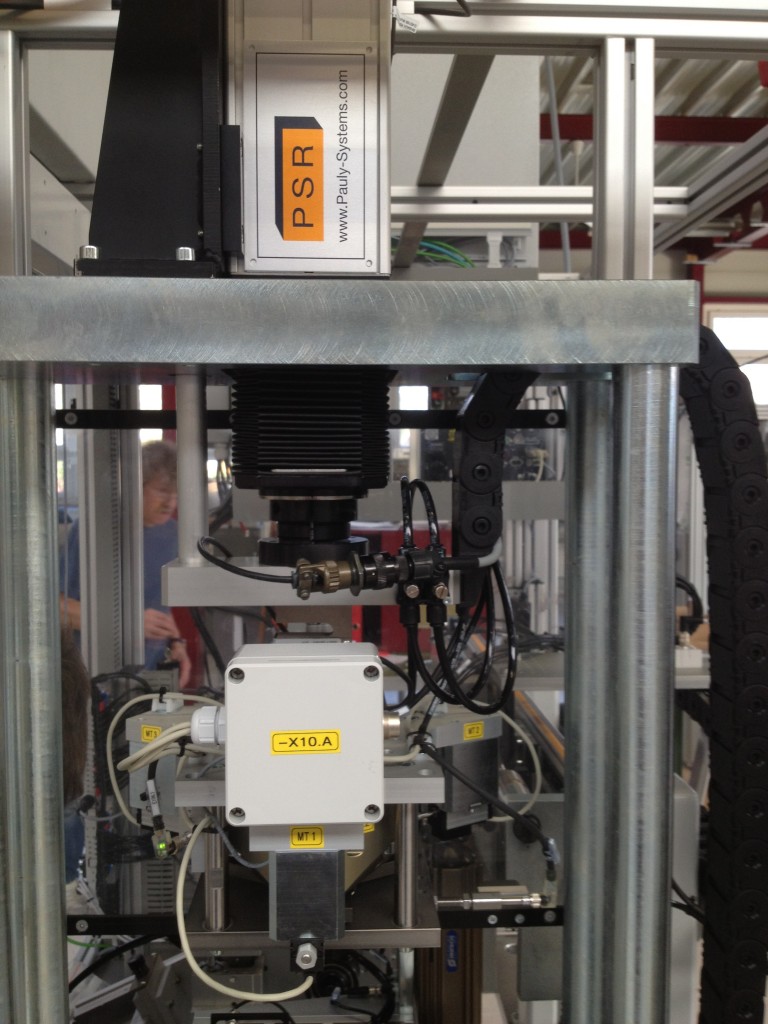

Hysteresis measuring machine for compensator elements

This force- and displacement-controlled machine is used to test automotive components for compression and tension. An electric linear axis with a load cell is used for this purpose. The axis position is measured redundantly via a linear encoder (SSI interface) and the Hyperface motor encoder. The force is measured with a load cell. Control and measured values are realized by one of our ERM modules, the load cell – connected via our EVAD box – provides both highly accurate and fast data.

The measured values are transferred to the PC via the Ethercat interface and displayed there

and archived.

The performance data:

Speed 0-300 mm/sec.

Load cell +/-2.5 kN

Accuracy 0.5 %